GPC Clean-up of Pesticides Residuals in Foods

| EV | · Suitable for fractionation of residual pesticides in food · Used in the purification preocess of test solution preparation method in Shoku-Au No.1003001 (October 3ed, 2006. Japan) of thw Pharmaceutical and Food Safety Bureau, MHLW, Section 2 “Simultaneous GC/MS (LC/MS) Analysis of Agricultual Chemicals in Livestock and Marine Products” |

| PAE | · Suitable for cleaning up water samlpes such as blood and bottom sediment · Highly effective for Fractionation of endocrine disruptors in environmental samples |

(GPC clean-up for residual pesticides in food, etc)

|

Product code

|

Product name

|

Particle size

(micron) |

Size(mm)

ID x Length |

|---|---|---|---|

| F6090005 | CLNpak EV-200 | 16 | 2.0 x 150 |

| F6090001 F6090002 |

CLNpak EV-2000 CLNpak EV-G |

16 16 |

20.0 x 300 20.0 x 100 |

| F6090003 F6090004 |

CLNpak EV-2000 AC CLNpak EV-G AC |

16 16 |

20.0 x 300 20.0 x 100 |

| Product name |

Max. sample load (mL) |

Max. usable pressure (MPa) |

Recommended flow rate (mL/min) |

Shipping

solvent |

|---|---|---|---|---|

| EV-200 |

0.2

|

2.5 | 0.05 |

Ethylacetate/Cyclohexane=3/7

|

| EV-2000 EV-G |

5

– |

2.5 – |

4.0 to 5.0 – |

Ethylacetate/Cyclohexane=3/7

Ethylacetate/Cyclohexane=3/7 |

| EV-2000 AC EV-G AC |

5

– |

2.5 – |

4.0 to 5.0 – |

Acetone/Cyclohexane=3/7

Acetone/Cyclohexane=3/7 |

Usable eluent : Acetone/Cyclohexan=1/9 to 5/5, Ethylacetate/Cyclohexane=1/9 to 5/5

(GPC clean-up for phthalic acid esters in sediments, bioogical samples, blood, etc)

|

Product code

|

Product name

|

Particle size

(micron) |

Size(mm)

ID x Length |

|---|---|---|---|

| F7600025 F6810022 F6714007 |

CLNpak PAE-800 CLNpak PAE-2000 CLNpak PAE-G |

5 5 9 |

8.0 x 300 20.0 x 300 8.0 x 50 |

| F7600026 F6810023 F6714008 |

CLNpak PAE-800 AC CLNpak PAE-2000 AC CLNpak PAE-G AC |

5 5 9 |

8.0 x 300 20.0 x 300 8.0 x 50 |

| Product name |

Max. sample load(mL) |

Max. usable pressure (MPa) |

Recommended flow rate (mL/min) |

Shipping

solvent |

|---|---|---|---|---|

| PAE-800 PAE-2000 PAE-G |

0.5

3 – |

4.0 5.0 – |

0.8 3.5 – |

Acetonitrile

Acetonitrile Acetonitrile |

| PAE-800 AC PAE-2000 AC PAE-G AC |

0.5 (water:10%)

3 (water:10%) – |

4.0 5.0 – |

0.8 3.5 – |

Acetone

Acetone Acetone |

Usable eluent : Acetone, Acetonitrile

Recently, the analysis of pesticides residues in many types of foods have become more important because of the increasing demand from EPA regulatory agencies.

The GPC (Gel Permeation Chromatography) clean-up method is widely used to remove lipids, polymers, pigments and other high molecular weight compounds from a wide range of sample matrices including food, tissues, grains, plants and environmental samples. Using this method combined with GC/MS, GC or HPLC, it is possible to detect many pesticides residues with good reproducibility in a relatively short period of time.

Dichloromethane has been used as an eluent for GPC clean-up, but as it may itself cause environmental pollution. To overcome this, the possibility of using a non-halogenated solvent such as ethyl acetate/cyclohexane as eluent was tested recently, but compared with dichloromethane the separation efficiency was inferior.

CLNpak EV-2000 series for GPC clean-up is developed to be used with non-halogenated solvents such as ethyl acetate/cyclohexane as the eluent. Using such solvents, EV-2000 series can obtain almost the same results when dichloromethane is used. This is the unique feature of EV-2000 series.

Analytical condition is following. You do not need special system. You can use CLNpak EV-2000 in usual HPLC system. Please use eluent of HPLC grade and analysis grade for pesticide residues.

| Elution volume of pesticides (total 100%) |

60 to 70 mL |

70 to 80 mL |

80 to 90 mL |

90 to 100 mL |

100 to 110 mL |

110 to 120 mL |

120 to 130 mL |

130 to 140 mL |

|

|---|---|---|---|---|---|---|---|---|---|

| fluvalinate | 16 | 84 | – | – | – | – | – | – | |

| chinomethionate | – | – | – | – | – | – | 100 | – | |

| Pyrethroid | cyhalothrin | – | 100 | – | – | – | – | – | – |

| flucythrinate | – | 64 | 36 | – | – | – | – | – | |

| cypermethrin | – | 28 | 72 | – | – | – | – | – | |

| cyfluthrin | – | 18 | 82 | – | – | – | – | – | |

| deltamethrin | – | – | 100 | – | – | – | – | – | |

| fenvalerate | – | – | 100 | – | – | – | – | – | |

| Organo- phosphorus |

terbufos | – | 4 | 96 | – | – | – | – | – |

| diazinon | – | – | 100 | – | – | – | – | – | |

| prothiofos | – | – | 98 | 2 | – | – | – | – | |

| pirimiphos methyl | – | – | 96 | 4 | – | – | – | – | |

| chlorpyrifos | – | – | 80 | 20 | – | – | – | – | |

| isofenphos | – | – | 33 | 67 | – | – | – | – | |

| malathion | – | – | 29 | 71 | – | – | – | – | |

| parathion | – | – | – | 100 | – | – | – | – | |

| phosalone | – | – | – | 98 | 2 | – | – | – | |

| phenthoate | – | – | – | 95 | 5 | – | – | – | |

| thiometon | – | – | – | 61 | 39 | – | – | – | |

| EPN | – | – | – | 7 | 93 | – | – | – | |

| fenitrothion | – | – | – | – | 98 | 2 | – | – | |

| fenthion | – | – | – | – | 95 | 5 | – | – | |

| dimethoate | – | – | – | – | 94 | 6 | – | – | |

| acephate | – | – | – | – | 75 | 25 | – | – | |

| methamidophos | – | – | – | – | – | 100 | – | – | |

| N-contg. | pretilachlor | 2 | 16 | 82 | – | – | – | – | – |

| pyridaben | – | 25 | 75 | – | – | – | – | – | |

| chlorpropham | – | – | 100 | – | – | – | – | – | |

| propanil | – | – | 100 | – | – | – | – | – | |

| bitertanol | – | – | 98 | 2 | – | – | – | – | |

| fenobucarb | – | – | 96 | 4 | – | – | – | – | |

| mepronil | – | – | 90 | 10 | – | – | – | – | |

| isoprocarb | – | – | 72 | 28 | – | – | – | – | |

| aldicarb | – | – | – | 100 | – | – | – | – | |

| ethiofencarb | – | – | – | 100 | – | – | – | – | |

| iprodione | – | – | – | 100 | – | – | – | – | |

| bendiocarb | – | – | – | 96 | 4 | – | – | – | |

| imibenconazole | – | – | – | 60 | 40 | – | – | – | |

| pirimicarb | – | – | – | 53 | 47 | – | – | – | |

| carbaryl | – | – | – | – | 61 | 35 | 4 | – | |

| mefenacet | – | – | – | – | – | 97 | 3 | – | |

| Organo- chlorine |

dicofol | – | – | 100 | – | – | – | – | – |

| vinclozolin | – | – | 100 | – | – | – | – | – | |

| aldrin | – | – | 96 | 4 | – | – | – | – | |

| beta-HCH | – | – | 86 | 14 | – | – | – | – | |

| alpha-HCH | – | – | 80 | 20 | – | – | – | – | |

| pp’-DDT | – | – | 72 | 28 | – | – | – | – | |

| pp’-DDE | – | – | 49 | 51 | – | – | – | – | |

| procymidone | – | – | 22 | 78 | – | – | – | – | |

| endosulfan | – | – | 17 | 83 | – | – | – | – | |

| methoxychlor | – | – | 3 | 42 | 55 | – | – | – | |

| dieldrin | – | – | – | 95 | 5 | – | – | – | |

| endrin | – | – | – | 89 | 11 | – | – | – | |

| captafol | – | – | – | – | 100 | – | – | – | |

| captan | – | – | – | – | 48 | 52 | – | – | |

| TPN | – | – | – | – | – | 100 | – | – | |

| phthalide | – | – | – | – | – | – | 90 | 10 | |

Columns : Shodex CLNpak EV-G AC (20mmID*100mm) + EV-2000 AC (20mmID*300mm) Eluent : Acetone/Cyclohexane=20/80 Flow rate : 4.0mL/min Column temp. : 40deg-C

Instead of dichloromethane which may cause the environmental pollution, non-halogenated solvent such as ethyl acetate and acetone can be used as eluent. Each solvent is mixed with cyclohexane and used for CLNpak EV-2000 series as the eluent. The effect of the solvents and their mixing ratio is shown below.

Sample :

1. 125mg/mL Corn oil

2. 1mg/2mL beta-Carotene

3. 1mg/2mL Fluvalinate

4. 0.3mg/2mL Chinomethionate

Columns : (Left); Shodex CLNpak EV-G AC (20mmID*100mm) + EV-2000 AC (20mmID*300mm)

(Center); Shodex CLNpak EV-2000 (20mmID*300mm)

(Right); Shodex CLNpak EV-G (20mmID*100mm) + EV-2000 (20mmID*300mm)

Eluent : (Left); Acetone/Cyclohexane

(Center); Ethyl acetate/Cyclohexane

(Right); Dichloromethane/Cyclohexane

Flow rate : 4.0mL/min

Detector : UV(254nm)

Column temp. : 25deg-C

CLNpak EV-2000 AC is used for GPC clean-up of pesticides residuals in food with acetone/cyclohexane eluent.

Sample :

1. Palmitic acid, 2. Oleic acid

3. Linolenic acid, 4. Fluvalinate

5. Chinomethionate, 6. beta-Carotene

7. Methoprene, 8. Cyhalothrin

9. Cyfluthrin, 10. Diazinon

11. Malathion, 12. Chloropyrifos-methyl

13. Corn oil, 14. Bis(2-ethylhexyl) phthalate

15. Methoxychlor, 16. Perylene

17. Sulfur

Columns : Shodex CLNpak EV-G AC (20mmID*100mm) + EV-2000 AC (20mmID*300mm) Eluent : Acetone/Cyclohexane=20/80 Flow rate : 5.0mL/min Detector : UV(254nm) Column temp. : 25deg-C

CLNpak EV-2000 is used for GPC clean-up of pesticides residuals in food with ethyl acetate/cyclohexane eluent.

Sample :

1. Palmitic acid, 2. Oleic acid

3. Linolenic acid, 4. Fluvalinate

5. Chinomethionate, 6. beta-Carotene

7. Methoprene, 8. Cyhalothrin

9. Cyfluthrin, 10. Diazinon

11. Malathion, 12. Chloropyrifos-methyl

13. Corn oil, 14. Bis(2-ethylhexyl) phthalate

15. Methoxychlor, 16. Perylene

17. Sulfur

Columns : Shodex CLNpak EV-G (20mmID*100mm) + EV-2000 (20mmID*300mm) Eluent : Ethyl acetate/Cyclohexane=20/80 Flow rate : 5.0mL/min Detector : UV(254nm) Column temp. : 25deg-C

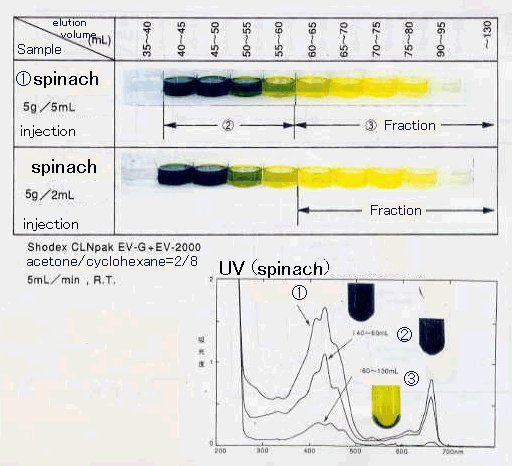

Removing pigment of spinach with CLNpak EV-2000 AC is shown.

Sample : Spinach

Columns : CLNpak EV-G AC (20mmID*100mm) + EV-2000 AC (20mmID*300mm) Eluent : Acetone/Cyclohexane=20/80 Flow rate : 5.0mL/min Detector : UV(254nm) Column temp. : 25deg-C

Recovery of pesticides residuals in spinach when CLNpak EV-2000 AC is used for GPC Clean-up of pesticides residuals is shown.

Sample :

1. Corn oil

2. Fluvalinate

3. Chinomethionate

| Injection as spinach |

Injection dry weight |

40 to 60mL | 60 to 130mL | Total recovery |

|---|---|---|---|---|

| 2.5g/5mL | 9.6mg | 9.3mg(97%) | 0.9mg(9%) | 106% |

| 5g/5mL | 19.3mg | 16.6mg(86%) | 2.0mg(10%) | 96% |

| 20g/5mL | 77.0mg | 68.5mg(89%) | 10.0mg(13%) | 102% |

Columns : Shodex CLNpak EV-G AC (20mmID*100mm) + EV-2000 AC (20mmID*300mm) Eluent : Acetone/Cyclohexane=20/80 Flow rate : 5.0mL/min Detector : UV(254nm) Column temp. : 25deg-C

Effect of sample injection volume when CLNpak EV-2000 AC is used for GPC clean-up of pesticides residuals in food is shown.

Sample :

1. Corn oil

2. Fluvalinate

Column : Shodex CLNpak EV-G AC (20mmID*100mm) + EV-2000 AC (20mmID*300mm) Eluent : Acetone/Cyclohexane=20/80 Flow rate : 5.0mL/min Detector : UV(254nm) Column temp. : 25deg-C

Effect of flow rate when CLNpak EV-2000 AC is used for GPC clean-up of pesticides residuals in food is shown.

Sample :

1. Corn oil

2. Bis(2-ethylhexyl) phthalate

3. Methoxychlor

4. Perylene

5. Sulfur

Columns : Shodex CLNpak EV-G AC (20mmID*100mm) + EV-2000 AC (20mmID*300mm) Eluent : Acetone/Cyclohexane=20/80 Detector : UV(254nm) Column temp. : 25deg-C

Effect of column temperature when CLNpak EV-2000 AC is used for GPC clean-up of pesticides residuals in foods is shown.

Sample :

1. Corn oil

2. Fluvalinate

3. Chinomethionate

Columns : CLNpak EV-G AC (20mmID*100mm) + EV-2000 AC (20mmID*300mm) Eluent : Acetone/Cyclohexane=20/80 Flow rate : 5.0mL/min Detector : UV(254nm)

The in-column solvent of CLNpak EV-2000 can be replaced easily without affecting column performance.

The column shipping solvent of EV-2000 column is ethyl acetate/cyclohexane(3/7).

(1) After pumping acetone/cyclohexane (2/8) at 2mL/min for 2h.

(2) After pumping ethyl acetate/cyclohexane (2/8) at 2mL/min for 2h.

(3) After pumping acetone/cyclohexane (2/8) at 2mL/min for 2h.

(4) After pumping ethyl acetate/cyclohexane (2/8) at 2mL/min for 2h.

Sample :

1. Corn oil

2. Fluvalinate

3. Chinomethionate

Columns : Shodex CLNpak EV-G (20mmID*100mm) + EV-2000 (20mmID*300mm) Flow rate : 4.0mL/min Detector : UV(254nm) Column temp. : 25deg-C

The in-column solvent of CLNpak EV-2000 can be replaced easily without affecting column performance.

The column shipping solvent of EV-2000 column is ethyl acetate/cyclohexane(3/7).

(1) After pumping dichloroethane/cyclohexane(3/7) at 2mL/min for 2h.

(2) After pumping acetone/cyclohexane(2/8) at 2mL/min for 2h.

(3) After pumping dichloroethane/cyclohexane(3/7) at 2mL/min for 2h.

(4) After pumping acetone/cyclohexane(2/8) at 2mL/min for 2h.

Sample :

1. Corn oil

2. Fluvalinate

3. Chinomethionate

Columns : Shodex CLNpak EV-G (20mmID*100mm) + EV-2000 (20mmID*300mm) Flow rate : 4.0mL/min Detector : UV(254nm) Column temp. : 25deg-C

The gel used for CLNpak EV-2000 AC has very good lot-to-lot reproducibility. The calibration curves of six different gel lots have almost same. The comparison of chromatograms of two lots among the six lots is also shown.

Sample :

1. beta-Carotene

2. Fluvalinate

3. Chinomethionate

4. Corn oil

5. Bis(2-ethylhexyl) phthalate

6. Methoxychlor

7. Perylene

8. Sulfur

Columns : Shodex CLNpak EV-G AC (20mmID*100mm) + EV-2000 AC (20mmID*300mm) Eluent : Acetone/Cyclohexane=30/70 Flow rate : 4.0mL/min Detector : UV(254nm) Column temp. : 25deg-C

Swelling data of CLNpak EV gel is shown. Swell of EV gel is the almost same with many kind of solvents. It means EV gel can be used with many kind of solvents safely.

Solvent and swelled volume of EV-2000 gel

The data of nother GPC gel for comparison

| Solvents | Degree of swelling (%) | |

|---|---|---|

|

EV-2000

|

Other GPC gel

|

|

| 1. 100% Acetone |

88

|

58

|

| 2. Acetone/Cyclohexane=50/50 |

94

|

82

|

| 3. Acetone/Cyclohexane=20/80 |

98

|

78

|

| 4. 100% Ethyl acetate |

95

|

73

|

| 5. Ethyl acetate/Cyclohexane=50/50 |

97

|

85

|

| 6. Ethyl acetate/Cyclohexane=20/80 |

94

|

77

|

| 7. 100% Dichloromethane |

100

|

100

|

| 8. Dichloromethane/Cyclohexane=50/50 |

104

|

103

|

| 9. Dichloromethane/Cyclohexane=30/70 |

102

|

93

|

| 10. Toluene/Cyclohexane=30/70 |

101

|

81

|

Ministry of Health, labour and welfare in Japan regulates maximum residue limits for agricultural chemicals in foods. Based on the revision of the “Food Sanitation Act” in 2003, “positive list system” was enacted May 29, 2006. In Food Sanitation Law #1003001 (Oct 3, 2006), section two states “Analytical method with GC/MS for multi-residues” and “Analytical method with LC/MS for multi-residues” in crops and animal products. In the method, gel permeation chromatography (GPC) has been adapted for the sample purification process. CLNpak EV-2000 AC is a column especially designed for the GPC clean up purpose. Below is the outline for the analytical method with GC/MS and LC/MS analysis for multi-residues.

Ministry of Health, labour and welfare in Japan regulates maximum residue limits for agricultural chemicals in foods. Based on the revision of the “Food Sanitation Law” in 2003, “positive list system” was enacted May 29, 2006. In Food Sanitation Law #1003001 (Oct 3, 2006), section two states “Analytical method with GC/MS for multi-residues” and “Analytical method with LC/MS for multi-residues” in crops and animal products. In the method, acrinathrin and tricyclazole were used as fractionation standards. For the purification of pesticide residuals in animal products, a GPC clean-up column, CLNpak EV-2000 AC is recommended.

Fractionation area is depending on the type of samples used for the GPC clean-up.

Sample : 5mL

Acrinathrin

Tricyclazole

Column : Shodex CLNpak EV-G AC (20.0mmID*100mm) + EV-2000 AC (20.0mmID*300mm) Eluent : Acetone/Cyclohexane=1/4 Flow rate : 5mL/min Detector : UV(254nm) Column temp. : 40deg-C

Fluvalinate and chinomethionate were previously used as fractionation standards. In Food Sanitation Law #1003001 (Oct 3, 2006), section two states “Analytical method with GC/MS for multi-residues” and “Analytical method with LC/MS for multi-residues” in crops and animal products. In the method, acrinathrin and tricyclazole were used as fractionation standards. Compared to the fluvalinate and chinomethionate fractionation area, the one obtained by acrinathrin and tricyclazole is wider.

Sample : 40mg/L each, 5mL

Acrinathrin

Tricyclazole

Fluvalinate

Chinomethionate

Column : Shodex CLNpak EV-G AC (20.0mmID*100mm) + EV-2000 AC (20.0mmID*300mm) Eluent : Acetone/Cyclohexane=1/4 Flow rate : 5mL/min Detector : UV(254nm) Column temp. : 40deg-C

Elution volume for lipid and fatty acids were monitored by CLNpak EV-2000 AC. Lipid and fatty acids elute fast, thus by fractionating between acrinathrin and tricyclazol, most lipid and fatty acids can be removed.

Sample : 5mL

Beef tallow

Acrinathrin

Tricyclazole

Oleic acid

Palmitic acid

Linolenic acid

Linoleic acid

Column : Shodex CLNpak EV-G AC (20.0mmID*100mm) + EV-2000 AC (20.0mmID*300mm) Eluent : Acetone/Cyclohexane=1/4 Flow rate : 5mL/min Detector : UV(254nm) Column temp. : 40deg-C

Two different temperature settings (room temerature and 40 deg-C) were compared for the GPC clean-up method using CLNpakEV-2000 AC. At room temperature, the high viscosity causes peak broadening and increases the analysis time. Therefore, analysis at 40 deg-C is preferred. In Food Sanitation Law #1003001 (Released by Ministry of Health, labour and welfare in Japan, 2006), analysis temperature is set at 40 deg-C.

Sample : 5mL

Fatty tuna

Acrinathrin 40mg/L

Tricyclazole 40mg/L

Column : Shodex CLNpak EV-G AC (20.0mmID*100mm) + EV-2000 AC (20.0mmID*300mm) Eluent : Acetone/Cyclohexane=1/4 Flow rate : 5mL/min Detector : UV(254nm)

Main separation mode for the GPC clean-up is size exclusion mode: based on analytes’ size differences, analytes are eluted in the order of their sizes. However, by optimizing the eluent composition, partition/adsorption mode can be also used. Change in acetone and cyclohexane ratio does not influence elution volume of lipid much. However by decreasing acetone, retention time of pesticides increases. At acetone/cyclohexane=3/7, lipid and acrinathirin co-elutes. In Food Sanitation Law #1003001 (Released by Ministry of Health, labour and welfare in Japan, 2006), the ratio of acetone/cyclohexane is set at 1/4.

Sample : 40mg/L each, 5mL

Acrinathrin

Tricyclazole

Column : Shodex CLNpak EV-G AC (20.0mmID*100mm) + EV-2000 AC (20.0mmID*300mm) Eluent : Acetone/Cyclohexane Flow rate : 5mL/min Detector : UV(254nm) Column temp. : 40deg-C